Precision CNC Machining Services

Quality Parts.

On Time.

Every Time.

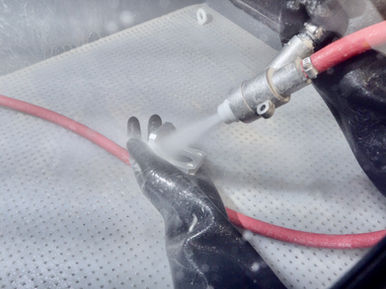

We make CNC Machined parts to your exact spec.

Argon Prototypes specializes in

fast-turnaround CNC Machining for R&D projects across Ontario.

• 5-Axis CNC Milling

• Aluminum, Steel, and Plastics

• Small to Mid-sized parts

• Order Quantities of 1 to 100

"Not your average machine shop..."

EASY to work with

Fast, transparent and informed communication... Our small and tight-knit team works closely to ensure an accurate and free flow of information at all times. We will update you throughout production and if you need to get in touch with us, you have a direct line to the shop floor!

Engineering Experts

When it comes to your engineering needs, we will always be on the same page. We are experts in machining, CAM, CAD, and are knowledgeable across many facets of mechanical engineering. Our skills enable us to work closely with your team to ensure your parts not only work, but are cost-effective.

Fast and agile

Short lead times are crucial for R&D: a single bottleneck can stall your entire project. For small-quantity orders, we typically ship within 1 to 2 weeks. Most machine shops don’t even want to touch prototype work and often quote lead times in months! We also reject large production runs to keep our schedule flexible.

Capabilities

Machinery

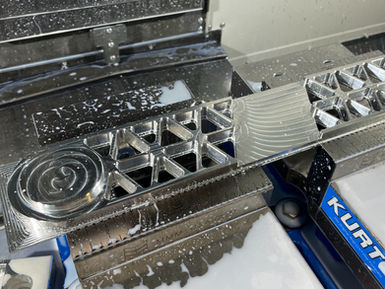

2022 GF MIKRON

MILL E 500 U

This high-performance 5-axis mill can tackle incredibly demanding parts with ease. Extreme precision, intricate geometries, ultra smooth finishes – this mill can do it all.

It is also equipped with an automated pallet system, greatly enhancing productivity for higher production orders.

-

5 Axis Milling (Simultaneous)

-

Direct Torque Motors

-

20k RPM Spindle

-

Automated pallet loading

-

60 Tool Magazine

-

19 x 17 x 15" Travels (X,Y,Z)

2021 Haas VF-2SS

with 4th Axis

This dependable CNC Mill boasts an impressive work envelope. With its 4th Axis Rotary, it can mill angled features with greater accuracy and efficiency than a standard 3-axis machine. Also, with 50% more travel in the X axis than our

5-Axis machine, it can machine larger parts.

-

3+1 Axis Milling (Positional)

-

12k RPM Spindle

-

High Speed Machining Software

-

Zero-Point Pallet System with 3 Vises

-

30 x 16 x 20" Travels (X,Y,Z)

-

25 x 12 x 15" Max. Part Size (X,Y,Z)